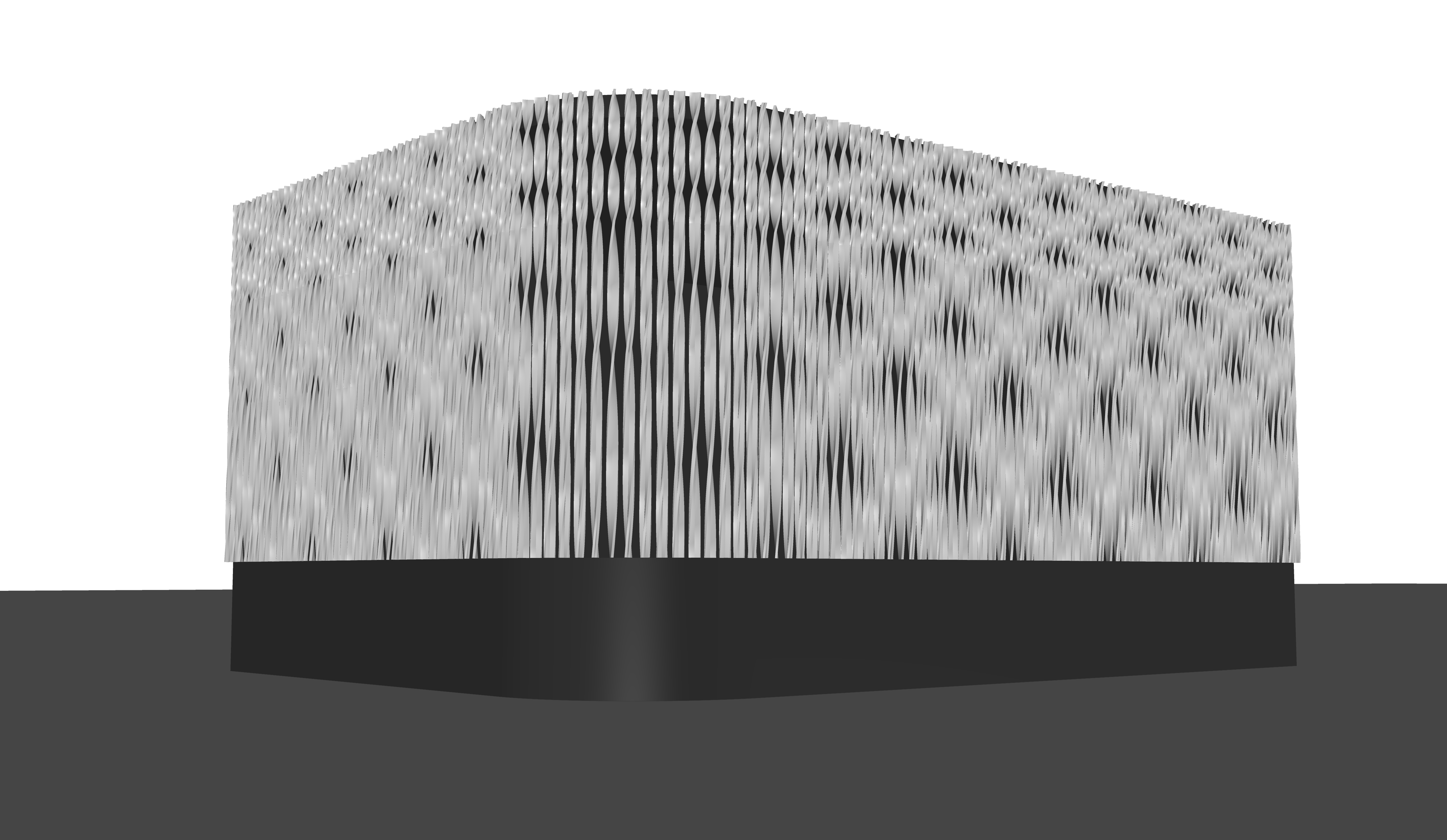

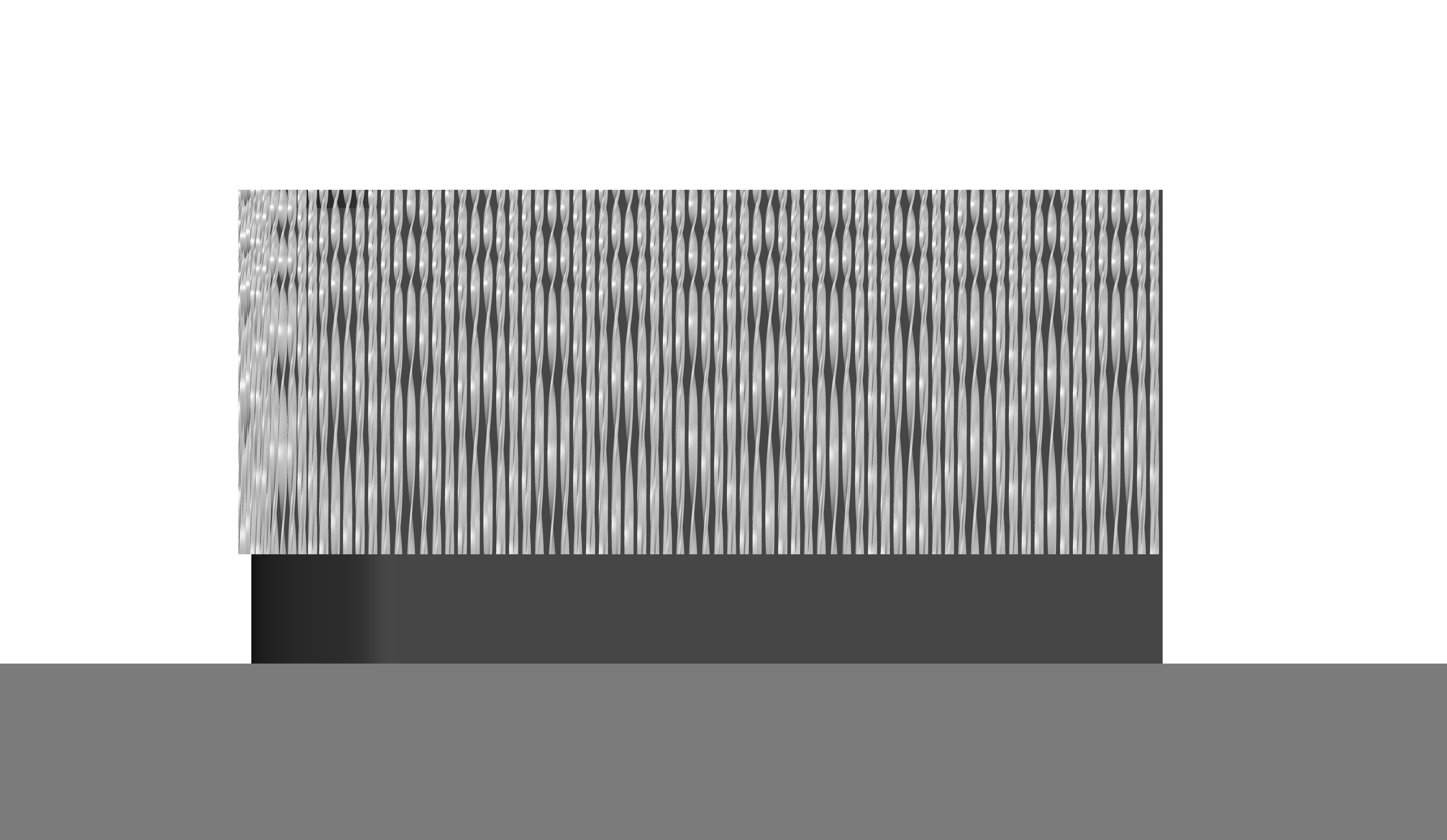

Study 3 – Leeds Carpark

Facade by ACME

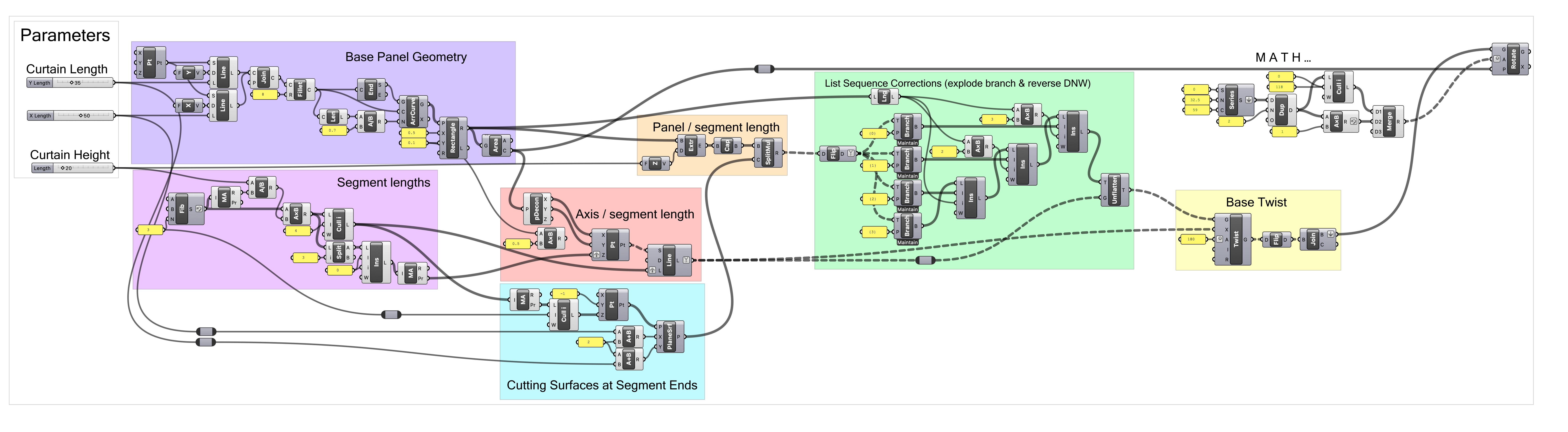

Script and methodology:

Parameter Setup: Using number sliders, the following are defined.

- X,Y Curtain lengths

- Curtain height

- Partition Fibonacci sequence

Base Panel Geometry: Panel geometry is arrayed along a curve defined by the curtain length parameters.

Segment Length Relation: To approximate the original facade, a scaled Fibonacci sequence of five elements is used to partition the curtain height. These define the extrusion segment lengths and rotation axes.

List Sequence and Grafting Considerations: A significant challenge arose due to the non-linear panel array. Each panel’s unique (x, y) coordinates meant that segment lengths were grafted in the z-direction, bottom to top, while remaining sequential like the panel array. However, the original divided extrusions intended for twisting (shown in the orange block) were organized according to dividing planes in the z-direction, resulting in panel groups that were sequential from top to bottom.

To resolve, the divided extrusion data was flipped, rows to columns. Still, the data in the individual data branch had to be reversed, while keeping the graft sequence constant. Due to the reduced branch quantity, this was done by splitting the data and re-inserting at a specific index.

Base Twist Geometry: With the original extrusion data matching the rotation axis data, baseline twisting of 180 degrees at each segment creates one gap region per segment.

Pattern Experimentation: Lastly, through some analysis of the original facade and experimentation, a sequence of additional rotation was used to create the illusion of gaps placed at varying intervals.

Results: