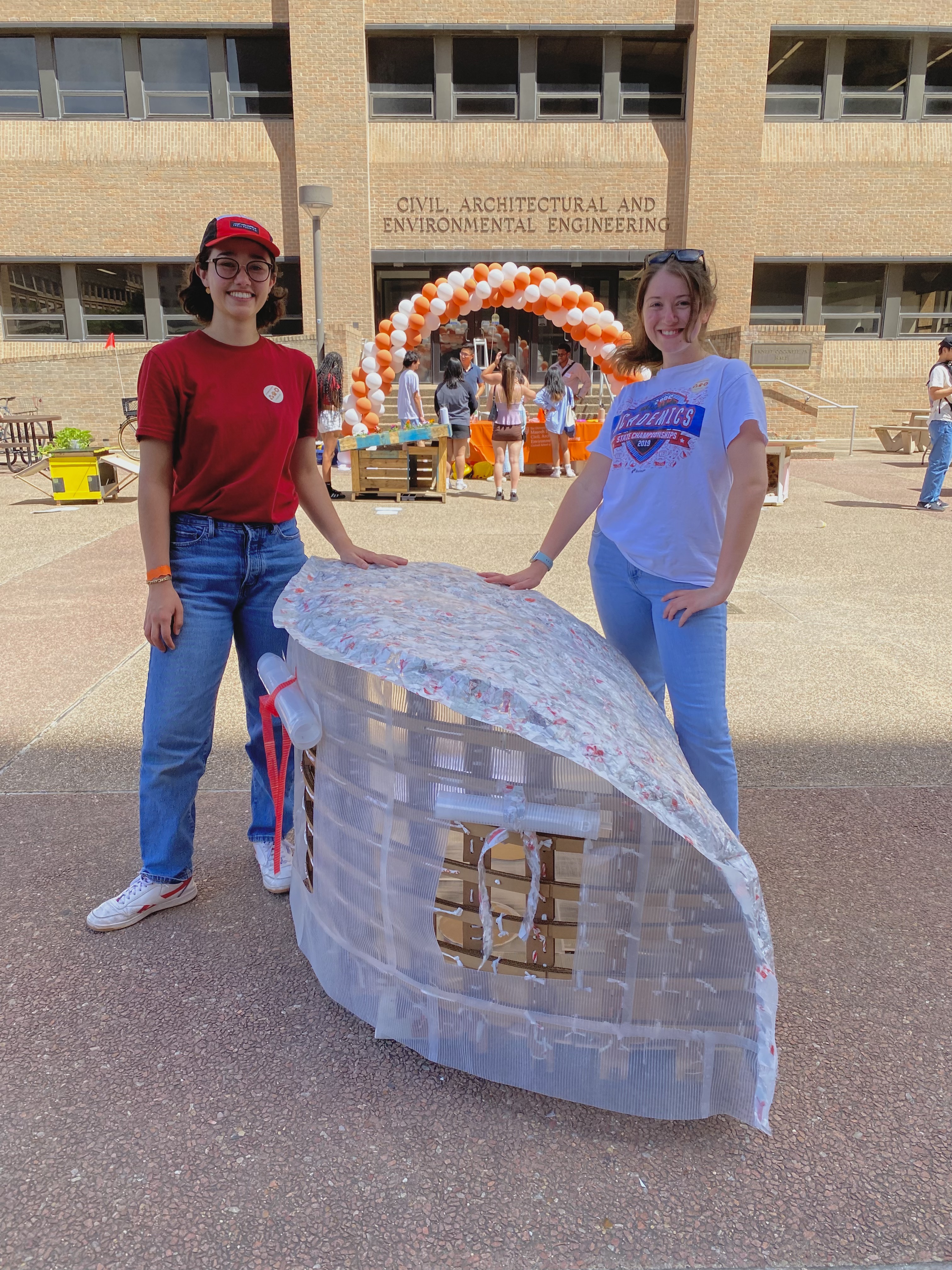

2024 Sustainable Doghouse Competition:

Plastic-Laminated Cardboard (PLC)

Project Scope: Build a viable doghouse able to withstand a 50 pound load and prevent water intrusion while employing sustainable practices in its material use and design.

Team Members:

Sofía Leal Cavazos – 3rd year Architectural Engineering

Rachel Berkley – 4th year Architecture

Design Considerations: Rigidity of cardboard joints, cross-sectional rigidity (lateral strength), material optimization, fabrication time.

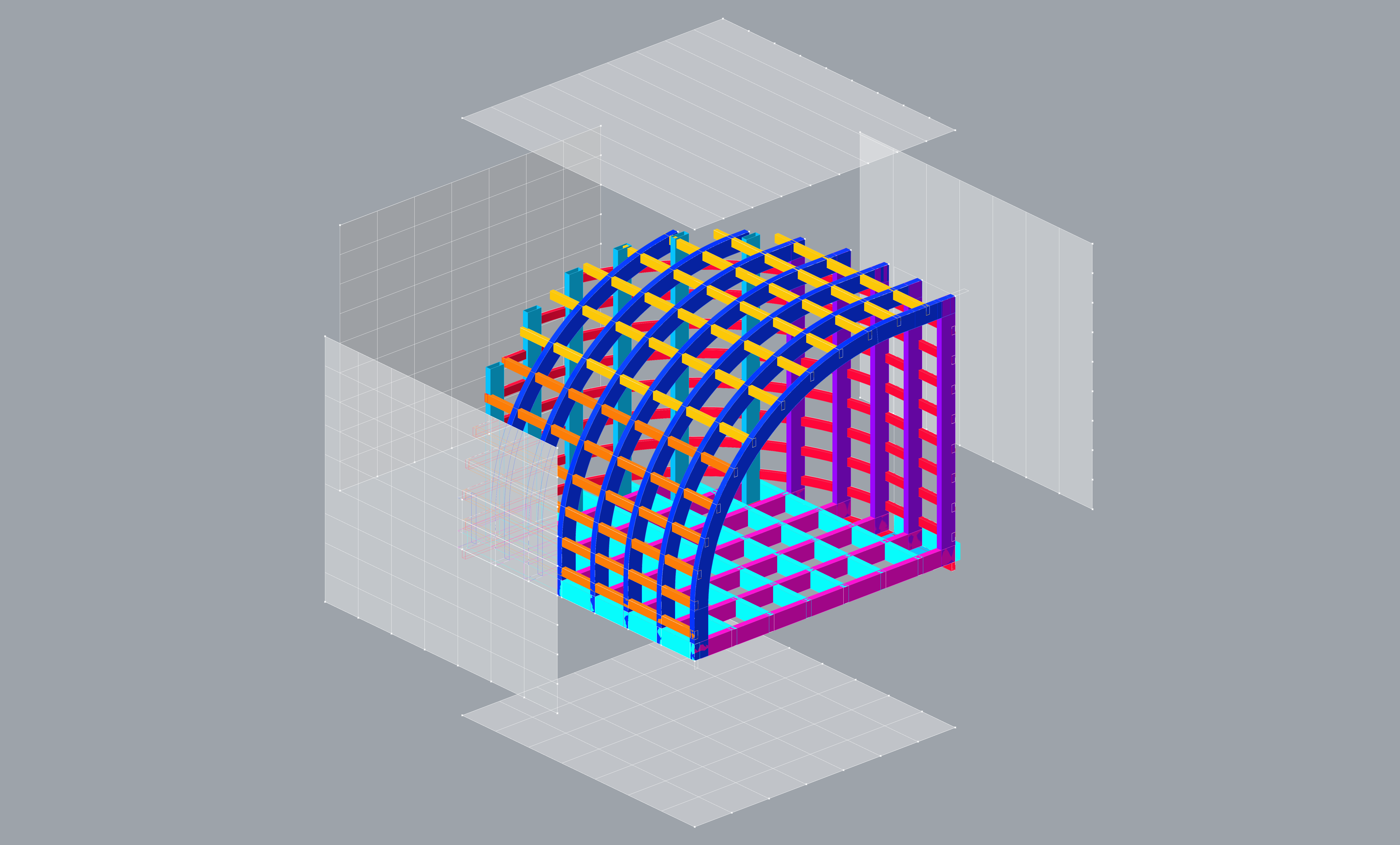

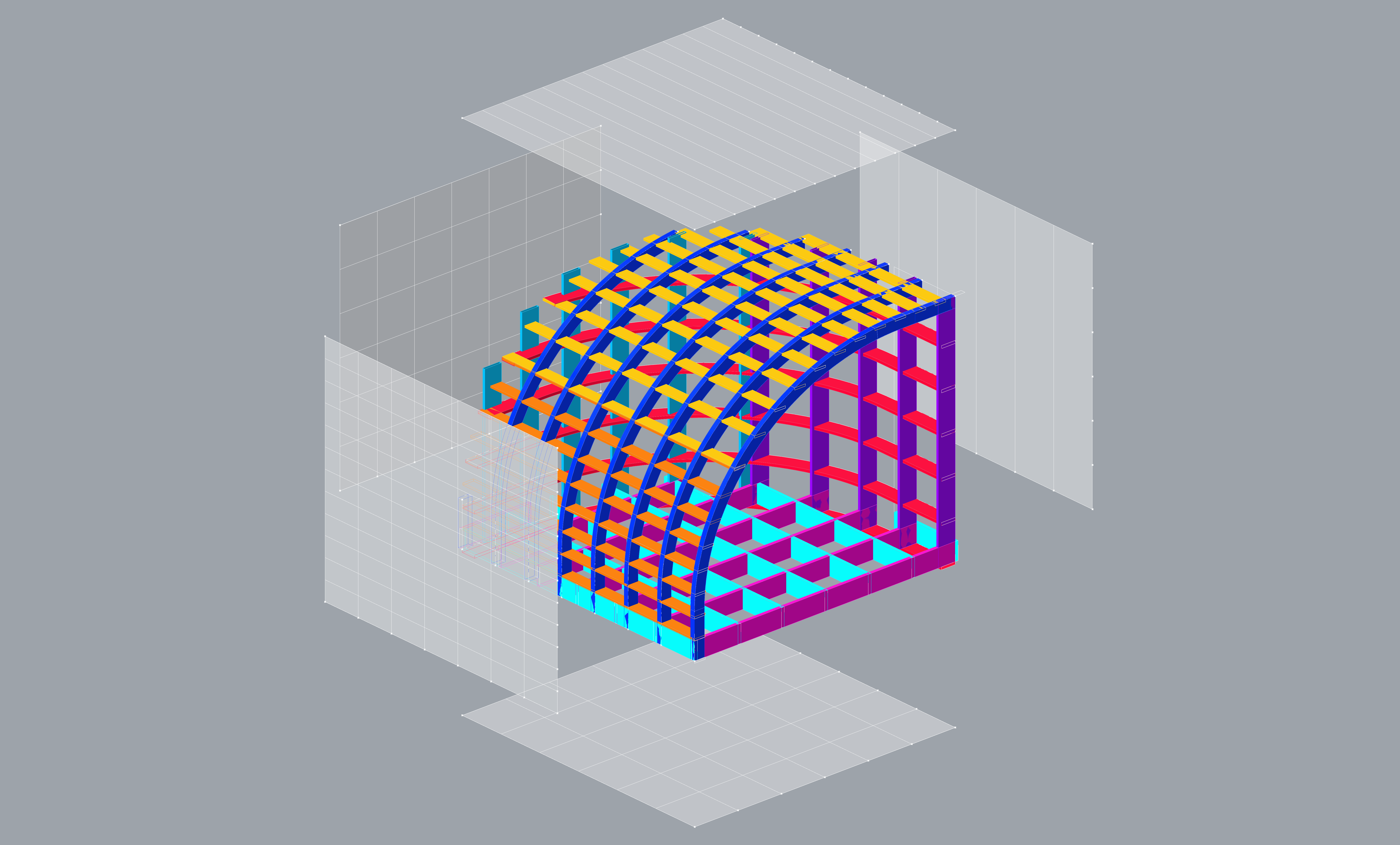

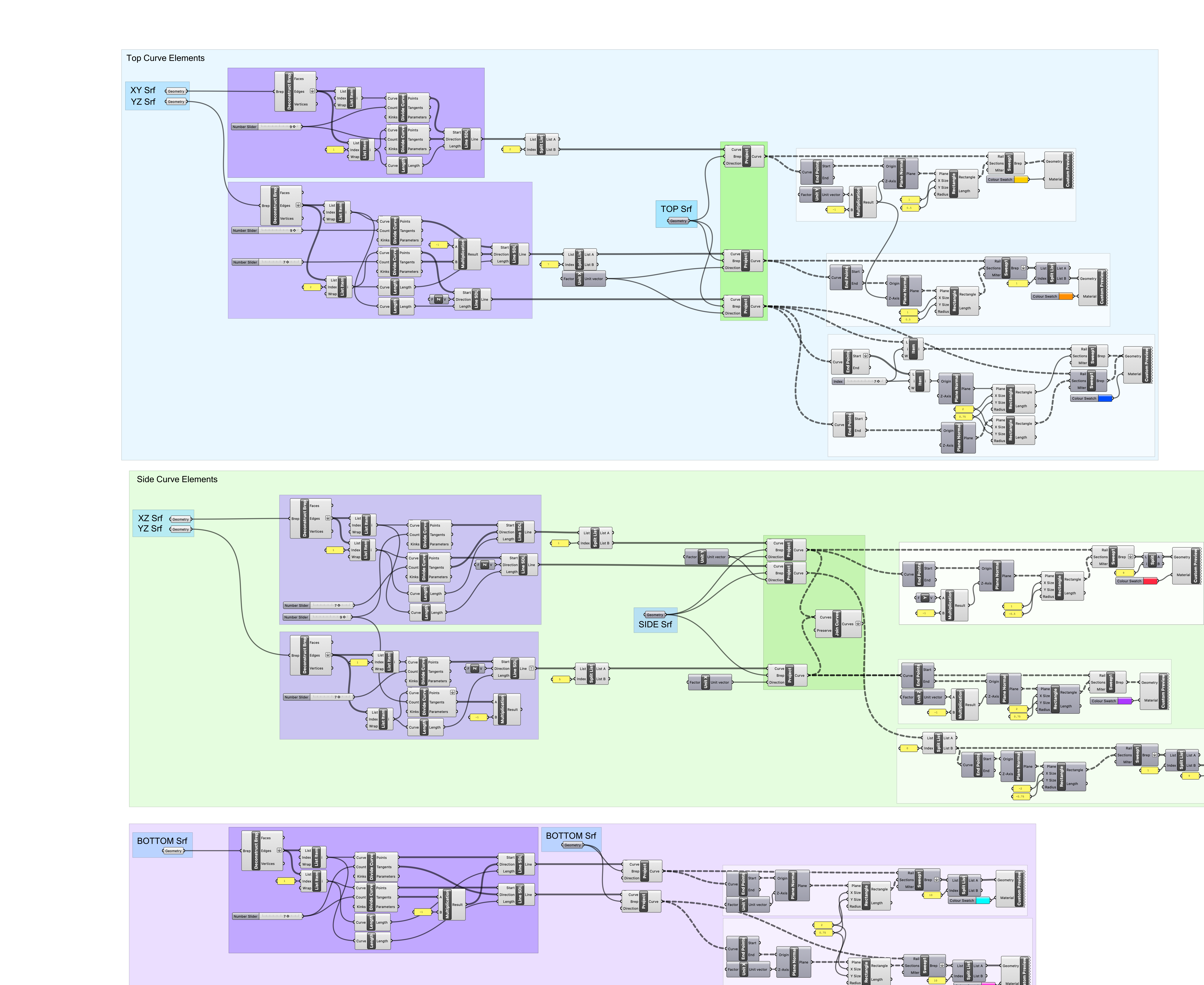

Since the cardboard strength wasn’t precisely known, I developed a grasshopper script to aid in the re-designing stages as we tested different cardboard joints and layer iterations.

Cardboard Structure:

Drawing inspiration from mass timber elements, particularly nail-laminated timber and cross-laminated timber, we decided to pursue corrugated cardboard as a building material. Employing cardboard’s directional rigidity and the tensile strength of plastic bags, we began fabrication of interlocking cardboard elements.

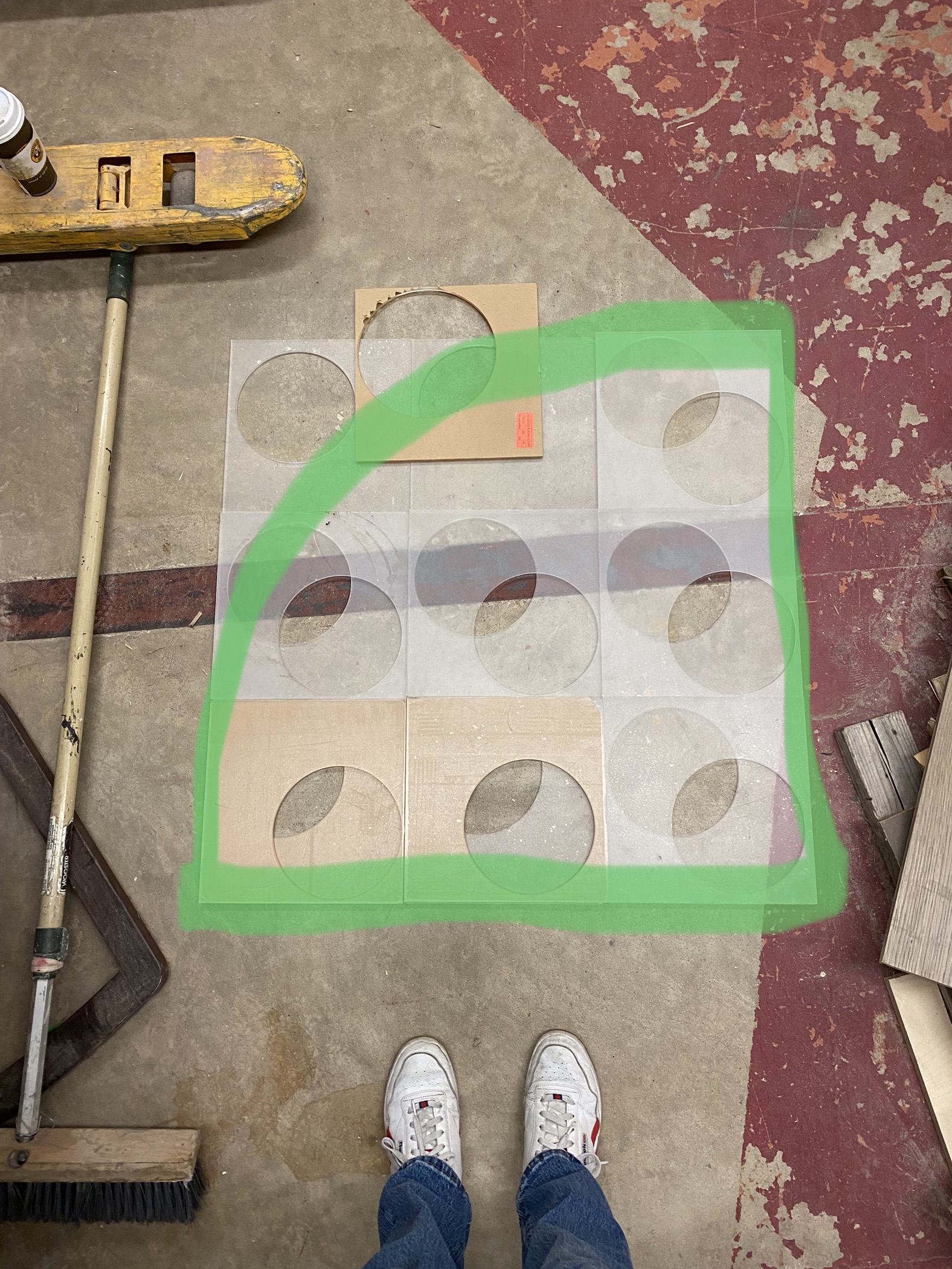

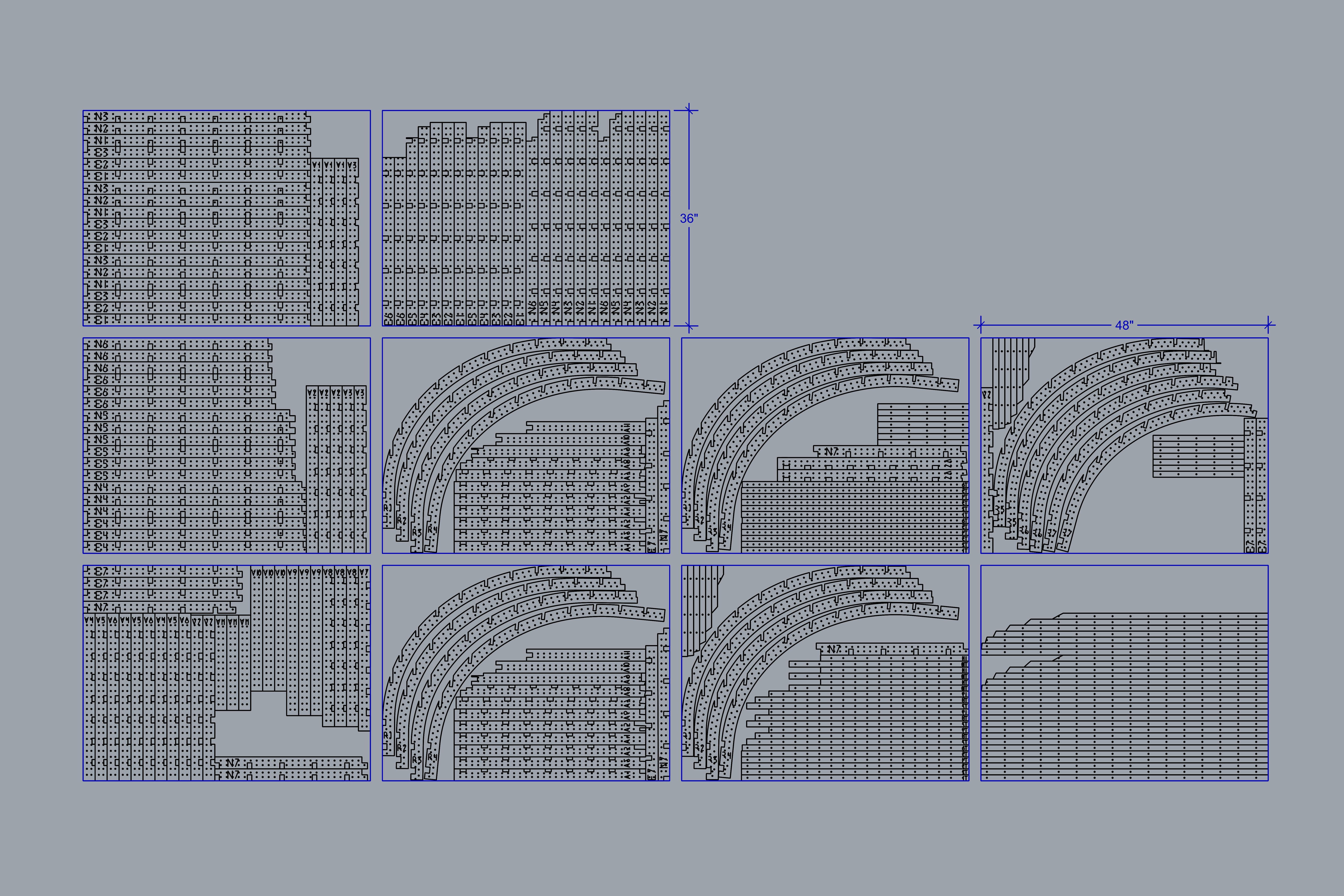

In the end, we were able to cut all necessary cardboard on ten 3’ x 4’ panels of 1/8” corrugated cardboard. Volumetrically, 1.25 cubic feet of material allowed us to create more than 15 cubic feet of usable interior, in addition to passing the 50-pound load test.

Envelope and Concrete Footings:

Through coordination with the construction materials classes, we were able to use waste concrete mix to cast five “footings” that would interlock with the cardboard base.

For the envelope, we fused our surplus of plastic scraps and an old shower curtain liner to create a reflective and resistant cover for the top/south face. Additional plastic panels were sourced at Habitat For Humanity’s ReStore.

Fabrication and Results: 2024 Sustainable Doghouse Winners